What should I do if the motor of a high-pressure cleaning machine is smoking?

Smoke from high-pressure cleaning machine motors is usually caused by an abnormally increasing current causing the circle to overheat, which may be caused by overload, abnormal power supply voltage, or mechanical failure. Here are the specific reasons and measures to address them:

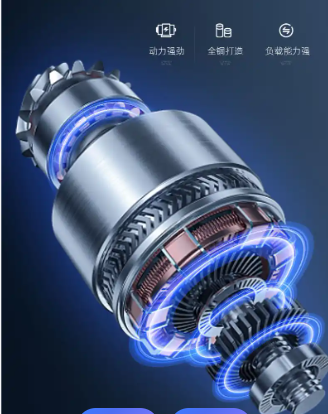

Analysis of common causes

1. Overloaded operation:

If the high pressure cleaning machine is overloaded for a long time (e.g., the high pressure pump is stuck, the pipe is blocked), the electric motor will increase the current due to the excessive load, and the circle temperature will rise rapidly to smoke. At this time, it is necessary to stop service immediately to check whether the pump body or the transmission parts are sluggish.

2. Problem with the power supply voltage.

Voltage below level or unstable: The motor needs more current to maintain power at low voltage level, resulting in increased copper loss, overheating and smoking.

Three-phase voltage imbalance or lack of phase: When a three-phase motor is run without a phase, the current of the unbroken phase cycle group increases sharply, and the insulation layer can be burned in a short time. The power supply line and switching touch points should be examined. 2

3. A mechanical failure.

Bearing damage or rotor sweep: lack of oil in the bearing, wear or bias in the rotor can lead to increased friction resistance and overload of the motor.

Fan malfunction or poor ventilation: Damage to a fan or dust clogging the ventilation channel can reduce heat dissipation efficiency and heat accumulation can cause smoke.

4. The ring insulation was damaged.

A stator cycle short circuit (interphase, phase) or grounding failure can directly cause the local current to become too large, and the insulation material to charred and smoke. This kind of breakdown needs the specialized examination, if uses the low voltage electric current flow method to locate the short circuit point.

Emergency treatment and maintenance advice

1. Immediate power outage: Quickly cut off the power supply after smoke is spotted to avoid the spread of the fault.

2. Preliminary inspection:

Odors: The charred odor of the insulation indicates damage to the ring; The charred smell may be due to overheating of the bearings.

Listen to sound: abnormal friction sounds indicate a mechanical failure; The hum may be a lack of phase.

3. Maintenance decisions:

If there is only a slight smoke and the insulation is not carbonized, it can be cleaned the motor, repaired the fan and tested.

If the coil is severely burned or the bearing is damaged because the performance of the silicate sheet is reduced when heated, it is usually recommended to replace the new motor rather than repair it.

4. Preventive measures:

Check the voltage stability of the power supply regularly to avoid overload.

Keep the motor ventilation channel clean and replenish the bearing lubrication in a timely manner.